Damascus steel is strong, but not the strongest metal there is.

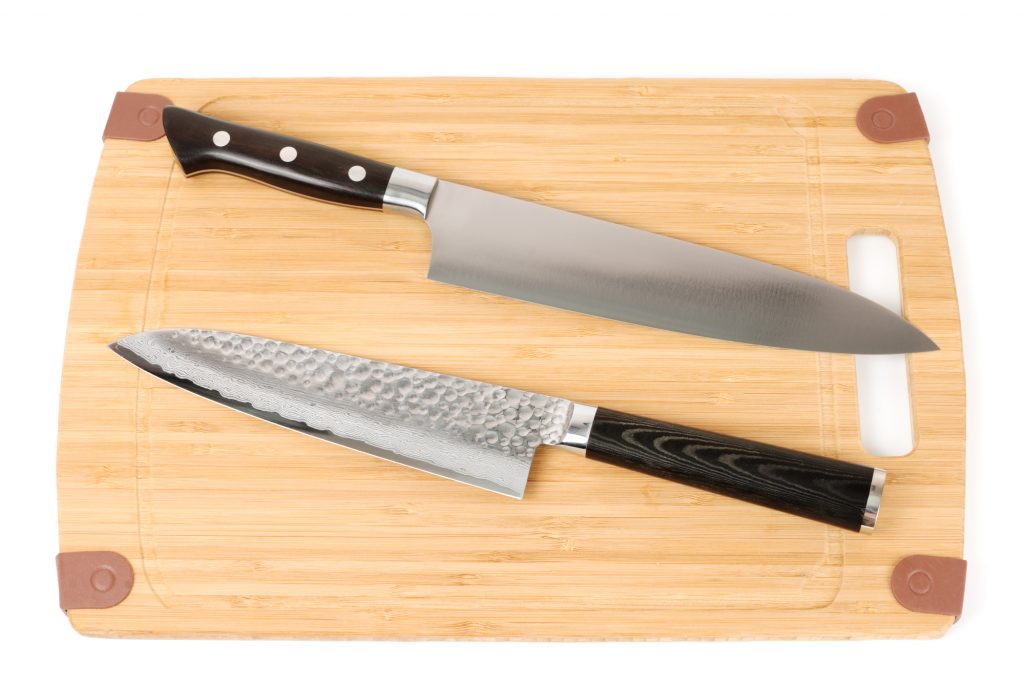

It is one of the more popular materials used in premium kitchen knives and meal preparation blades because of its natural strength and durability. It also has an excellent aesthetic appeal that elevates the overall look of a blade.

Here is a bit of history about Damascus steel and why so many of the products we at Knives Academy review have a Damascus steel option.

What is Damascus Steel?

The term “Damascus steel” can be confusing, referring both to a type of metal forging technique and the resulting blade material. The metal forging technique has historically been used to produce swords and blades dating back centuries and originating from the Middle East (specifically, Syria, India, and Persia).

It was popularized by European swordsmiths in the early 20th century and involved folding alternating layers of ferrite/pearlite and carbide-rich martensite over one another during repeated heating and hammering processes. It produces an attractive pattern on the surface of the metal, which contributes to Damascus’ popularity with knife enthusiasts today.

Is Damascus Steel Better than Regular Steel?

Damascus steel is highly sought-after, but it has downsides too. For one thing, it’s expensive. The process of making Damascus steel is challenging, so any knives made from this material will cost you more.

Additionally, if you’re looking for a knife that doubles as an everyday carry item and one that can take a beating, Damascus steel may not be your best bet. While the pattern looks cool and adds to the overall appeal of these knives, it does not necessarily make them stronger than other types of steel. It all comes down to the manufacturing process to ensure high durability.

How is Damascus Steel Forged?

To understand how steel is made, you need to know what a metal alloy is. An alloy combines two or more types of metals to create a new metal that has different properties than the original material. The most common alloys in knife making are:

- Low carbon steel

- High carbon steel

- Stainless steel

Carbon steels are those that have up to 1.65 percent carbon by weight. The more carbon that is added, the harder and stronger the steel becomes. However, it also becomes more brittle and difficult to forge, sharpen, and weld.

Carbon steels with less than 0.3 percent carbon are known as mild steels and have good toughness (ability to resist shock), and can be easily formed into various shapes. Steels with about 0.6 percent carbon are called medium-carbon steels because they balance ductility (expand under tension) with strength derived from the addition of alloying elements.

Most Damascus steel blades are made with a high carbon element.

What Makes that Attractive Pattern?

One technique that is used to create Damascus steel involves layering the metals together and forming them into a billet. When creating Damascus steel knives, metals are added to form billets in different patterns. The billets are then heated, hammered until they’re flattened, and folded over onto more layers of metal. This process can be repeated many times, depending on the thickness of the blade being forged.

The more layers of metal there are in a billet, the more intricate the pattern on a piece of Damascus steel can be. There are usually between 600-800 layers when a knife is made using this method. The folding helps to reinforce these areas. As you fold them over and over again, you place grain boundaries together where they become harder than other parts of the blade. This makes them strong enough to handle regular use without compromising flexibility or being prone to chipping during use or sharpening.

Types of Damascus Steel

The strength of the blade is not just due to the type of steel used but also because of the way it’s made. Two different types of steel are used – soft and hard.

The soft steel forms the core of the blade, while the hard steel is used to form the cutting edge. The soft steel is folded around the cutting edge. This allows it to be sharpened without affecting the strength of the blade. So even though both types of steel are being sharpened at once, you can still maintain a razor-sharp edge without worrying about damaging your knife.

So what makes Damascus knives so popular? Well, one reason might be that it’s easier to sharpen than most other blades on the market today. If you’re using one made from high carbon stainless steel (which many are), then all you need to do is wipe it down with water or oil after every use and never worry about rusting again.

Factors Affecting Damascus Steel Quality

The final factors that will affect the choice of metals for your Damascus steel weapon are more practical than aesthetic. These include:

- The type of blade it will be used for: For example, a chef’s knife is going to be more useful when it has a thicker blade and less edge flexibility.

- The quality and type of steel used

- The thickness of the blade

- The weight of the blade

- The length of the blade

- The width of the blade (the tang)

- Quality edge retention

How Much Should a Damascus Knife Cost?

Damascus steel knives are quite expensive. You’ll be looking at $100 and up—and that’s just for the blade. A custom knife can cost you upwards of $1,000, but it will last a lifetime.

As for how much you should spend on one yourself, it depends on what kind of use it gets. If you’re using your Damascus blade as an occasional carving or slicing tool for special occasions (or if it’s strictly for decoration), then you can get away with spending less than if you were planning to use it daily in your kitchen or outdoors.

How to Maintain Damascus Steel Knives?

Damascus steel is strong, durable, and beautiful. But, you will want to properly care for your Damascus steel knives if you hope to enjoy them for years to come. The following tips will help ensure that your Damascus steel knives stay in top condition:

- Use a high-quality knife sharpener specifically designed for Damascus steel when sharpening the blade.

- Wash with soap and water after every use and dry immediately.

- Store your Damascus steel knives in a safe place where they won’t be exposed to moisture or extreme temperatures. It’s best if they are stored in a wooden block or sheath made from leather or canvas. Apply a light coating of oil on the blade before storing it away, both at home or while traveling.

- Never put any type of knife in the dishwasher since this can cause damage to the blade and handle. Also, avoid using harsh chemicals or abrasives when washing as these can discolor the metal and/or damage the handle itself.

Damascus is an Excellent Blade Material

We at Knives Academy put out buying guides and top-rated lists of quality kitchen knives like cleavers, fillet knives, and even paring knives for general use. We always try to include at least one Damascus steel option because so many consumers love the design pattern and enhanced durability. We hope this article has informed you about what Damascus steel has to offer.

Post Your Thoughts